Oil Refinery Process Control/SCADA

The Philadelphia region historically has been an area with a rich heritage of petrochemical processing. Chevron, Atlantic-Richfield/ARCO, Sun Oil/Sunoco are some of the names in the business which have been located in and around Philadelphia.

Sunoco is the biggest name in the area, and I worked on real-time systems in most of the Sun refineries. At one time there were five Sun refineries: Philadelphia, Tulsa, Toledo, Marcus Hook, and Yabucoa. Each of these refineries had a series of process control systems installed to manage chemical processes, keep track of inventory, minimize expense, and control environment outputs like smokestack emissions. My team installed the original data acquisition system used in those refineries.

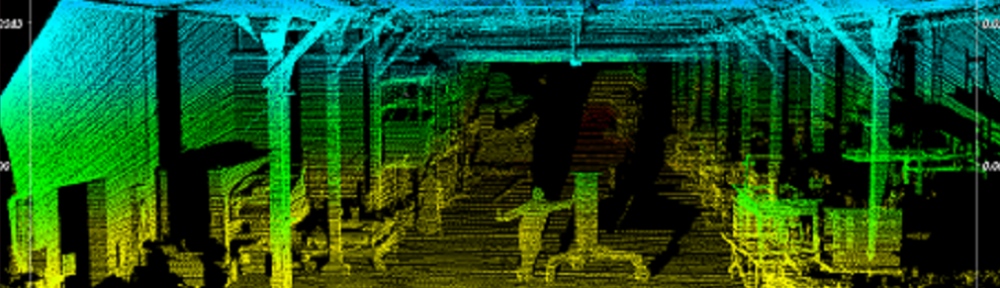

By combining process control systems from Honeywell, Allen-Bradley, and others with computer systems monitoring inputs from those control systems, making programmatic decisions, and writing data to the control system bus, many subsystems in the refining process were automated or more easily monitored.

One example of this, is working within EPA regulation. For example, a regulation might say ‘a refinery can “blow soot” into the air for three straight minutes, but only within one hour of the clock’. If you can control this “soot blowing” to start at three minutes before the hour, then the refinery can legally “blow soot” for a full six minute period (three before/three after) thus maximizing the “soot” expelled, and still work within regulation.

Our system is capable of doing a variety of tasks, including the one described above, and also enabled any computer with access to the refinery LAN to monitor or control any instrumented process taking place within the refinery.